Sand Separators Hydrocyclone Filters Industrial water Prefiltration

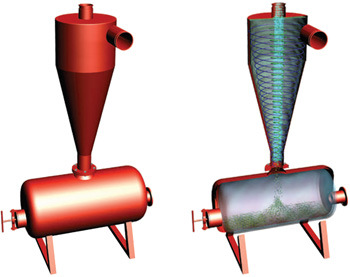

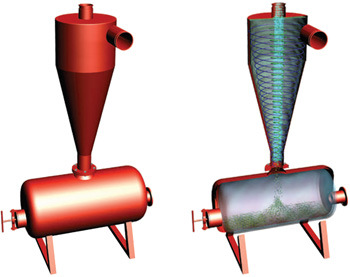

The hydro-cyclone filters has been designed and built on the principle of free flow, where water flows freely on a spiral path along the length of the filter's cylinder. As the result of the centrifugal force, waste becomes separated from the water and adheres to the filter's walls. It then gravitates downwards to be collected in an underflow chamber, while the purified water rises to emerge from the top end of the filter.

The materials and sophisticated design guarantees an extremely long product life.

Product Description:

A Hydro cyclone separates sand and other solid matter from water with very little head loss and 90% or better efficiency. There is no head loss build up and no clogging when the solids are separated. Hydro cyclones are easy to operate and maintain, and have no moving parts or screens.

Versatility in system configurations and ease of installation are some of its great advantages.

A Hydro cyclone uses a tangential injection flow process, enhancing the centrifugal forces and moving solid particles outwards. The dispersed particles move downward in a spiral path into an underflow chamber (sedimentation tank) while clean liquid moves upwards to the centre of the spiral, towards the top outlet.

A specially designed rubber insert protects the neck of the Hydro cyclone from erosion and increases separation efficiency. The Sedimentation Tank can be drained automatically with an automatic flushing kit (an electric valve, controller and small command filter). Automatic flushing will not interfere with the proper functioning of the Hydro cyclone. The Hydro cyclone has a 100 micron protective coating of extra durable polyester applied electrostatically and oven cured on a zinc-phosphate layer for maximal anti-corrosion protection.

Standard Features:

- Inlet / Outlet on an axis of 90 degrees

- Inlet and outlet through quick coupling [v] connectors enabling flexibility and easy assembly. (The filters may also be assembled by threaded [m] connections or by flange [f] connectors, as desired).

- Electrostatic oven curing with an epoxy-polyester combination at a thickness 150 micron, or alternatively, hot galvanization at a thickness 100 micron

- Maximum recommended working pressure up to 8bar

Working principle

Hydrocyclone sand separator is based on the principle of centrifugal sedimentation and density difference, At a certain pressure, the flow into the device, have a strong rotary motion, due to the different densities of sand and water, under the effect of centrifugal force, centripetal buoyancy, fluid drag force, so that the low density of the water rises, discharged from the overflow port, high density of sand from the bottom, so as to achieve the purpose of grit removal. Under certain terms and conditions, the higher water pressure,

the higher the grit removal rate, it can also be fixed in parallel.

Scope of application

1,Domestic and industrial: river water, ground water, well water grit removal, coal washing water, industrial processing, solid-liquid separation;

2,Geothermal air conditioning water system to replace the current use of Ah type fan coil before decontamination, the complete elimination of the fan coil clogging dirt deposition and cooling water systems chiller condenser water decontamination, impurity control suspended solids and other issues;

3,Recycling water reuse: especially for steel, thermal, chemical, petroleum, mining, pharmaceutical, textile, electronics, food, paper and other industrial local quality miscellaneous drainage treatment and reuse;

4,Water, sewage treatment: reused water, sewage treatment plant, reduce fine filtration system into operation

Technical parameters:

Model of sand filter |

Flow rate

(T/h) | Water inlet (mm) | Water outlet (mm) | Ø diameter of cylinder

(mm) | A1

(mm) | B1

(mm) | B2

(mm) | H1

(mm) | H2

(mm) | H3

(mm) |

| YLXC–40I | 25 | 40 | 25 | 273 | 220 | 113 | 220 | 640 | 140 | 860 |

| YLXC–50I | 40 | 50 | 25 | 273 | 220 | 108 | 230 | 680 | 140 | 910 |

| YLXC–65I | 50 | 65 | 25 | 325 | 220 | 124 | 240 | 780 | 140 | 1030 |

| YLXC–80I | 60 | 80 | 40 | 325 | 220 | 118 | 250 | 830 | 180 | 1095 |

| YLXC–100I | 100 | 100 | 40 | 377 | 220 | 134 | 260 | 920 | 200 | 1205 |

| YLXC–125I | 160 | 125 | 50 | 377 | 320 | 122 | 300 | 980 | 200 | 1310 |

| YLXC–150I | 200 | 150 | 50 | 478 | 380 | 150 | 360 | 1010 | 200 | 1410 |

| YLXC–200I | 250 | 200 | 50 | 620 | 440 | 200 | 430 | 1065 | 200 | 1550 |

| YLXC–250I | 300 | 250 | 65 | 720 | 500 | 225 | 520 | 1170 | 200 | 1750 |

| YLXC–300I | 500 | 300 | 65 | 820 | 580 | 274 | 590 | 1375 | 250 | 1990 |

Installation Precautions

1. Hydrocyclone sand separator should be installed in the main pipe of water supply network and fixed on the

base, we need to add a bypass between the inlet and outlet.

2. In order to ensure smooth water flow in front of the device should be installed intake and intake period equal

diameter of straight pipe length equivalent to 10 to 15 times the diameter of the intake.

3. The equipment should be installed around the reserve has enough space for maintenance.

4.During normal operation, the need to open the inlet and outlet valves, close the drain valve and bypass valve.

5.depending on how much sand content of regular source of water decontamination platoon sand, open the

drain valve at the sewage, water can flow out until the sewage process does not affect the normal use of water.

6.After sewage, close the drain valve.

7. If lack of sand discharge pressure, close the valve at the outlet.

Jiangsu YLD Water Processing Equipment Co., Ltd. is a high-tech enterprise, specialized in the research, development, design, manufacture, installation, technical consultation and personnel training.

We mainly produce electronic scale removal, UV sterilization, filtration, softening and cyclone grit removal technology and equipment. With strong technical force and rich experience, our company strictly implements ISO9001 system in the plan and management. "High technology leads to market development" is our basic concept.

We have extensively cooperated with domestic key universities, research institutions and foreign professional manufacturers, such as DOW (Dow) Chemical Co., Ltd., HYDRANAUTICS (Hydranautics) Company, Company (a professional manufacturer of multi-stage pumps), MILTONROY (Milton) Corporation (a metering pump manufacturer), the US Soft Controller KINETICO and OSMONICS, We have also fully introduced advanced technology. Thus, our technology is always in the leading domestic level. Over the years, our company has specialized in a variety of water treatment equipment for food, beverage, pharmaceutical, hospital, precision electronic, fine chemical, electricity, painting and surface cleaning industries.

Our "LYD" high-quality products at reasonable prices and perfect after-sales services have won great trust from worldwide customers,

We are willing to cooperate with the friends from all over the world and creat fine future together!