Palm Plantation Captive Power Plant

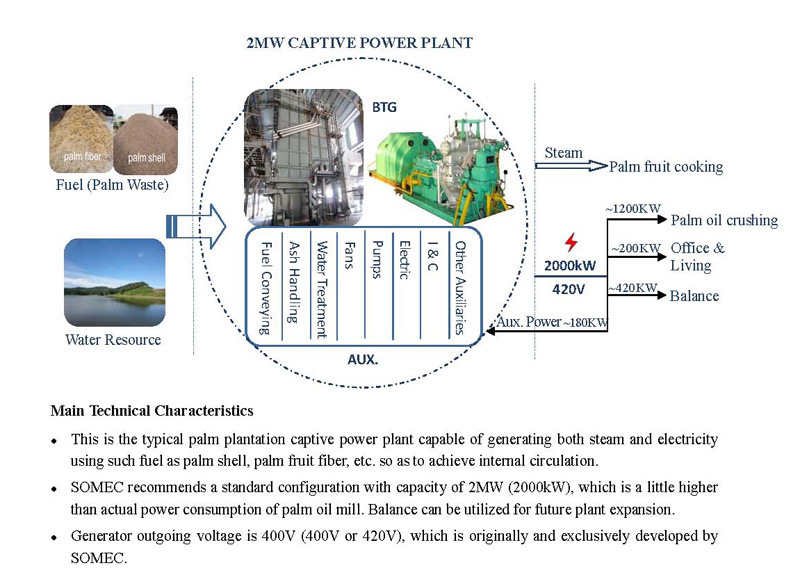

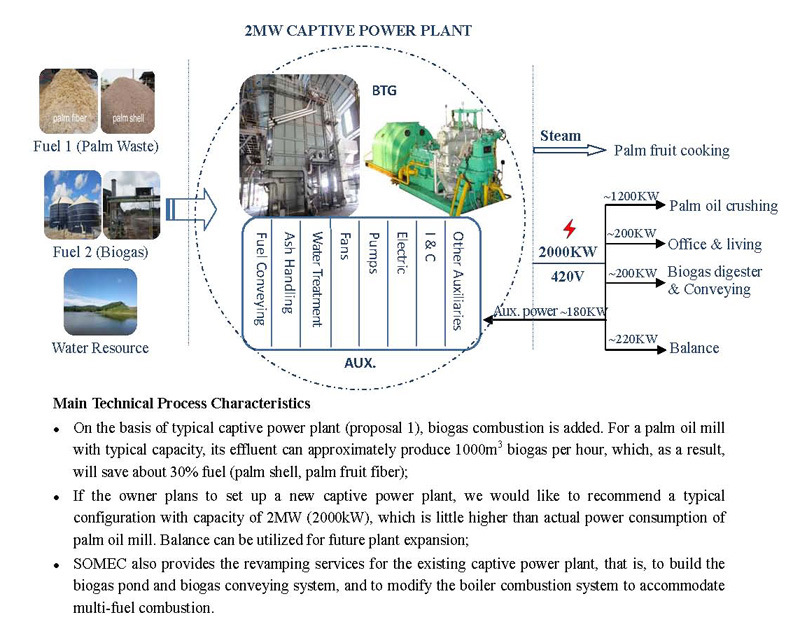

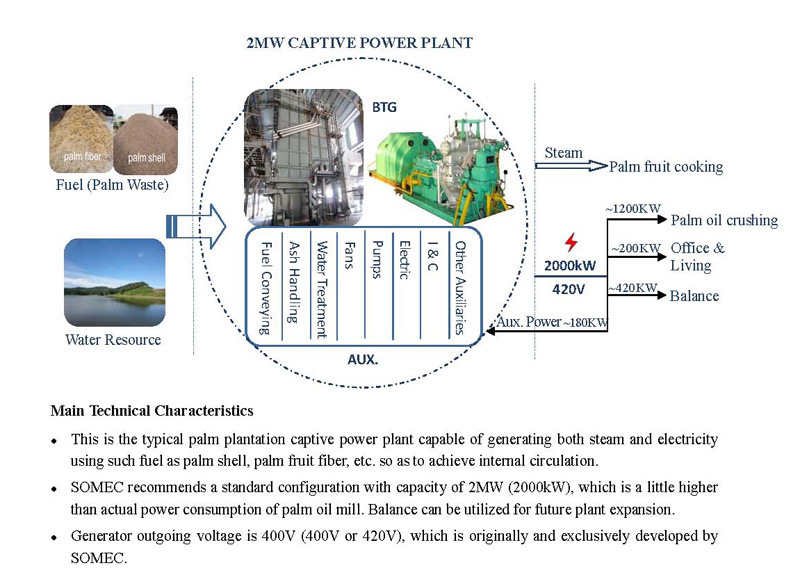

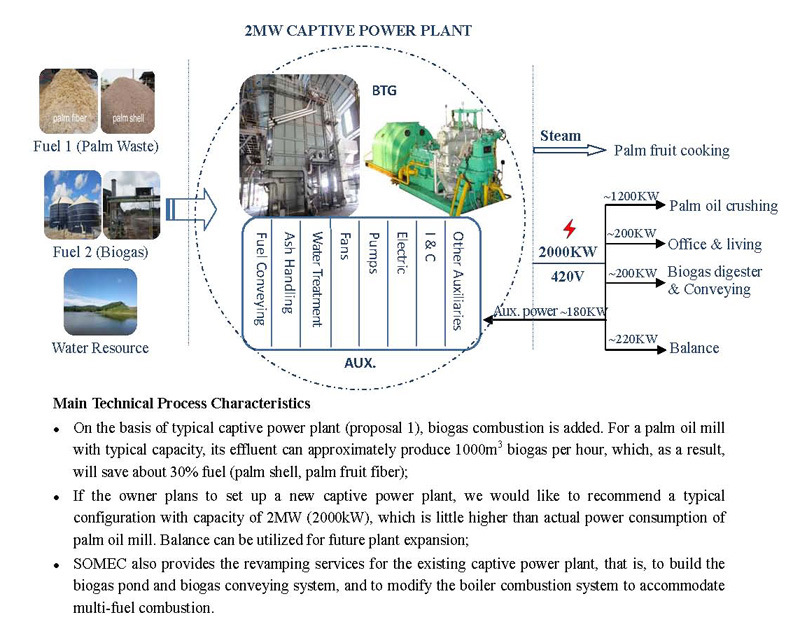

Usually one palm plantation of 20~30 thousand acres needs to be adopted a palm oil crushing plant, which electricity load is around 1700KW~ 1800KW. Taking into account the living electricity and other facilities usage, the captive power plant suitable capacity shall be around 2000KW. Since all the palm oil crushing plant equipments power voltage is 400V, therefore we choose the generator with output voltage 420V.

Palm oil crushing process requires lots of steam, and generates lots of palm empty bunches, palm fruit fibers, palm shells, kernels and other wastes. The special designed biomass boiler can burn these palm wastes and generate steam, which through back pressure turbine generator to generate electricity and then directly cooking the palm oil. This approach not only can meet the electricity and steam requirements, but also can solve the palm waste disposal problem.

Design Proposal

General principle: The equipment and system shall be safe, reliable, practical and easy to operate with mature process design.

Capacity: Single BTG unit, that is one palm waste fired boiler(35~45t/h) of sub-medium temperature and sub-medium pressure combined with one unit of 2000KW turbine generator(back pressure type).

Plant layout: Compact and reasonable arrangement with smooth access.

Fuel conveying system: Fuel is conveyed from the palm waste shed to the furnace hopper and fed in to the furnace for combustion.

Water system: Power plant water using river water or lake water(rainwater), the circulating cooling system is open cycle.

Chemical water: Using desalinization equipment, water pre-treatment +R/O system.

Electric system: Generator output voltage is 0.42KV, which will be connected to the owner's existing distribution room, with one 400V line to the power plant.

Control system: Boiler, turbo unit, generator, deaerator feedwater using single-loop control system, equipped with world well-know brand DCS + PLC.

Slag and ash handling: Using multi-tube dust remover, slag and ash will be transported outside by truck, no ash yard in the plant.

Proposal 1: Fuel of Plam Waste

Proposal 2: Fuel of Plam Waste + Biogas

Shandong Overseas Machinery & Equipment I/E Co., Ltd. (SOMEC) was developed from the Overseas Project Dept. Of Shandong Machinery & Equipment Group Corporation, and jointly set up with some certain energy enterprises which is dedicated to the operation of international EPC projects/complete plants.

In last decade, SOMEC has enjoyed rapid development in electric energy projects, and successfully provided complete power plants as well as equipment / system / parts / service to overseas customers, such as:

PT. Poeser Indonesia / PT. Lombok Energi

PT. PLN (Persero) (BBL Project)

PT. PLN (Persero) (NTT project)

PT. Great Giant Pineapple

PT. Indominco Mandiri

Zedtee Plywood Sdn. Bhd

PT. Surabaya Mekabox

PT. Basuki Pratama Engineering

Mitsubishi Heavy Industries

Sinar Mas Group

T. Uttam Galva Metallics Limited

etc.

Being one of the earliest in operation of overseas projects, since 1990s, we provided various products and services for a good number of domestic and foreign users, including:

Mitsubishi Heavy Industries / Main supplier for steel structure, shipbuilding platform, etc.

China Ministry of Railways / Qualified Supplier for electrified railway cable, overhead lines, etc.

Qingdao & Tianjin Municipal / Main Contractor for coal gasification projects

Djajanti Group, Indonesia / EPC contractor for cold storage, ice-making plant on its eight aquatic bases

Djajanti Group, Indonesia / Main supplier for fishing boats, diesel engines and diesel generating sets, etc.

Djajanti Group, Indonesia / Main supplier for one shipbuilding line in Indonesia

Premier Industrial Chemical / EP contractor for ethanol production line of 100, 000 tons per year.

Myanmar Ministry of Industry / EPC contractor for quinine extraction plant, other pharmaceutical facilities.

With support from the group corporation and high authorizes, awarded with the international engineering qualification issued by China Ministry of Commerce, we are ready to provide you the best service and share the success of every project.