Product introduction

NIPHOS water processor is composed of joint pipes, barrels, inlet and outlet strainers, blind flange and fasteners. It is mounted on pipe. It can make NIPHOS particles flow into the pipe from the outlet, ensure equipment (including heating equipment and pump) and instrument in proper operation and make NIPHOS stably dissolved, so as to ensure safety production.

Working principle

When the concentration of silicon phosphate in living water treatment agent is 3-5ppm, silicon phosphate can generate soluble complex and nano-sized insoluble membrane to inhibit scale and prevent corrosion, and to effectively prevent second pollution. The water contains many metal ions such as calcium (Ca), magnesium (Mg) and ferrum (Fe) which are easy to generate insoluble substances on the inner wall of water supplying pipeline, such as calcium carbonate and magnesium carbonate. Polyphosphates contained in living water treatment agent can generate soluble complex by reacting with metal irons. Complex can prevent generation of calcium carbonate and magnesium carbonate, be dispersed in water and react with Fe, and then generate dynamic protective film on inner wall of pipeline to prevent corrosion and scale.

Scope of application

NIPHOS water processor is widely used in residential buildings, restaurants and hotels, tall buildings, hospitals, sauna and bath centers and factories to prevent corruption and scale formation of water supply pipes. Especially applicable for:

1. Agents for drinking water treatment

2. Cooling water and hot water heat exchanger of central air— Conditioning

3. Reverse osmosis membrane of large pure water treatment equipment

4. Ice machine, coffee machine, humidifier, dishwasher, washing machine, solar water heater and household water purifier, etc.

5. Tea boiler, hot water boiler, wall— Hanging stove, geothermal system and water heater, etc.

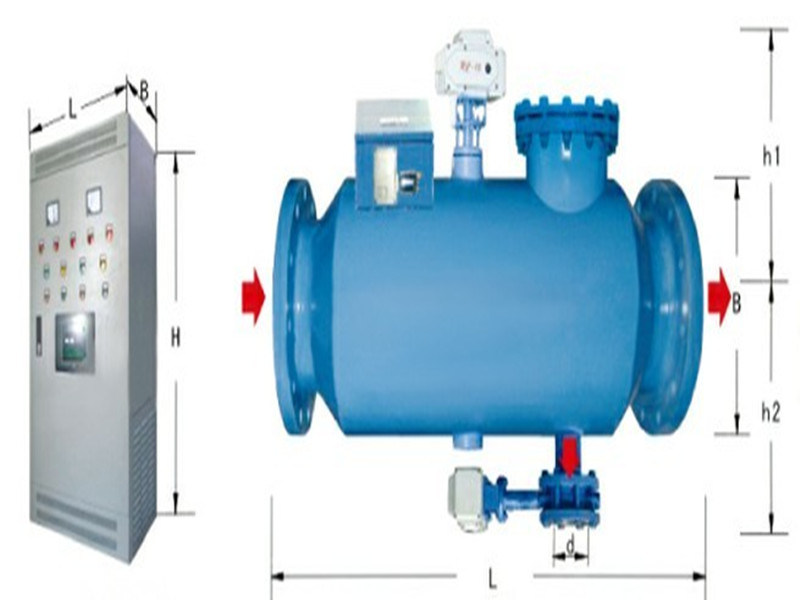

General principle for selection of NIPHOS water processor

1. Tank capacity and drift diameters of inlet and outlet: Equipment capacity should be calculated based on daily water consumption and inlet water hardness. In principle, the inlet and outlet diameter of NIPHOS tank should not be less than that of the matching pump, which is usually the same as that of inlet pipe;

2. Nominal pressure: Pressure grade of filter should be determined based on the maximum pressure filtration pipeline;

3. The number of holes; The number of holes should be determined mainly based on the diameter of intercepted NIPHOS particles and in accordance with media flow process;

4, Materials of NIPHOS water processor: The material of NIPHOS tank is usually the same as that of joint process pipes. Filters made of plastics, glass fiber reinforced plastics, carbon steel, low-alloy steel or stainless steel should be selected depending on different reaction conditions.

Comparison of electronic water processor and NIPHOS water processor

NIPHOS water processor can be used for corrosion prevention and scale inhibition; But cannot be used to kill bacteria and algae. As a kind of nutrient, phosphate will be absorbed by algae and thus algae will grow faster. (The amount of added agents should be limited) In terms of corrosion prevention and scale inhibition, NIPHOS water processor is better than electronic water process.

Instructions

1. Before operating equipment system, rinse system pipeline first. Before rinsing system pipeline, close inlet and outlet valves and open by— Pass valve.

2. Normal operation

1) Carefully check pipelines and valves

2) After checking, open inlet and outlet valves, and close by— Pass valve.

3. NIPHOS should be kept in 1 gram to 5 gram per ton of water to achieve desired results, and thus, users should add NIPHOS every 3 to 6 months.

| Model | Fluid (m3/hour) | fluid(m3/day) | volume(L) | diameter of barrel (mm) | height of barrel(mm) | dosing volume (Liter) | Height of water inlet(mm) | height of water outlet(mm) |

| YAT-10 | 0.1 | 2.5 | 0.5 | 160 | 450 | 0.5 | 120 | 40 |

| YAT-20 | 0.1-0.2 | 2.5-5 | 1.5 | 160 | 710 | 1.5 | 120 | 40 |

| YAT-30 | 0.2-0.4 | 5-10 | 3.5 | 230 | 470 | 3.5 | 120 | 40 |

| YAT-40 | 0.4-0.6 | 10-15 | 5.5 | 230 | 710 | 5 | 135 | 45 |

| YAT-50 | 0.6-0.8 | 15-20 | 7.5 | 230 | 1110 | 7 | 160 | 45 |

| YAT-60 | 0.8-1.5 | 20-35 | 13 | 230 | 1100 | 10 | 160 | 50 |

| YAT-70 | 1.5-2.5 | 35-60 | 30 | 230 | 1210 | 20 | 160 | 60 |

| YAT-80 | 2.5-3.5 | 60-85 | 40 | 300 | 1100 | 30 | 350 | 150 |

| YAT-90 | 3.5-4.6 | 85-110 | 55 | 400 | 1350 | 40 | 350 | 150 |

| YAT-100 | 4.6-7.1 | 110-170 | 80 | 450 | 1450 | 50 | 450 | 200 |

| YAT-110 | 7.1-9.2 | 170-220 | 100 | 500 | 1650 | 80 | 680 | 430 |

| YAT-120 | 9.2-12.1 | 220-290 | 130 | 600 | 1750 | 100 | 700 | 450 |

| YAT-130 | 12.1-18.3 | 290-440 | 180 | 700 | 1850 | 150 | 700 | 450 |

| YAT-140 | 18.3-30 | 440-720 | 260 | 800 | 1850 | 200 | 700 | 450 |

Jiangsu YLD Water Processing Equipment Co., Ltd. is a high-tech enterprise, specialized in the research, development, design, manufacture, installation, technical consultation and personnel training.

We mainly produce electronic scale removal, UV sterilization, filtration, softening and cyclone grit removal technology and equipment. With strong technical force and rich experience, our company strictly implements ISO9001 system in the plan and management. "High technology leads to market development" is our basic concept.

We have extensively cooperated with domestic key universities, research institutions and foreign professional manufacturers, such as DOW (Dow) Chemical Co., Ltd., HYDRANAUTICS (Hydranautics) Company, Company (a professional manufacturer of multi-stage pumps), MILTONROY (Milton) Corporation (a metering pump manufacturer), the US Soft Controller KINETICO and OSMONICS, We have also fully introduced advanced technology. Thus, our technology is always in the leading domestic level. Over the years, our company has specialized in a variety of water treatment equipment for food, beverage, pharmaceutical, hospital, precision electronic, fine chemical, electricity, painting and surface cleaning industries.

Our "LYD" high-quality products at reasonable prices and perfect after-sales services have won great trust from worldwide customers,

We are willing to cooperate with the friends from all over the world and creat fine future together!