China Professional Factory Coal Gasifier

| Price: |

US $ 5000/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1set |

| Pay Type: |

L/C,T/T |

The main features of coal gasifier(1)main equipmenthave small investment

(2)quick start

(3)safe and convenient

(4)easy to operate

(4)save 20% fuel than the direct oil-burning. Use the hot gas can save over 60% of energy economy compared to direct fuel thermal processing furnace

(5)has a significant effect of dust collection, protect environment, is the essential equipment of hot-processing systems

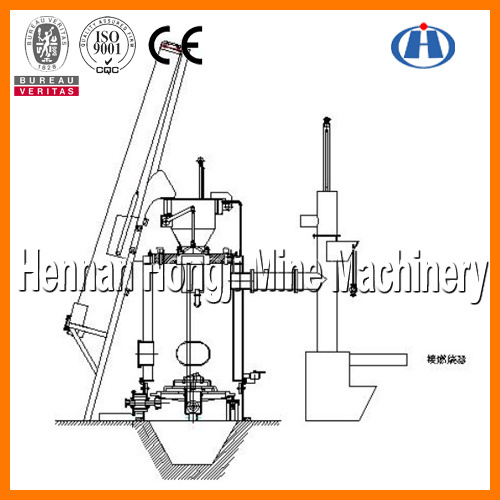

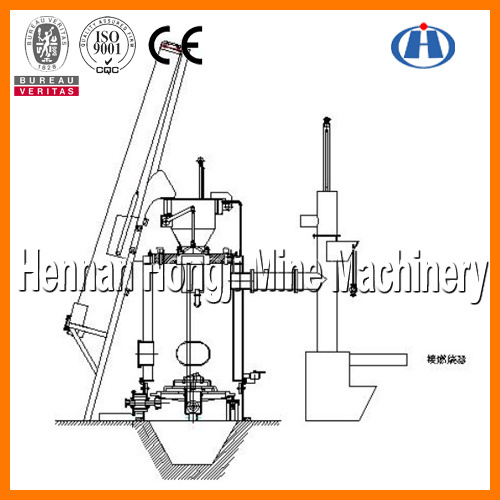

Application of Coal Gas gasifierCoal Gasifier which designed and manufactured by our company, use air and water vapor as the gasification agent, is the advanced equipment.

Coal Gasifier uses air and vapor as the gasifying agents to produce mixed gas. It is suitable for gasifying coking coal, hard coke, etc. and is widely used in machinery, metallurgy, chemistry, glass, building materials, food, textile and light industries.There are single stage and two stage gasifier for different quality of output gas.

Export country of the Coal GasifierIndia, Vietnam, Kazakhstan, Mongolia, Ecuador, Iran, Pakistan, Australia, the Middle East and other countries and areas.

Working Principle of the Coal GasifierUse the scientific technology structure to analyze water molecules, produced H2, CH4, CO, O2 combustible mixed gas. During the process, oxygen (02) for helping combustion, so that the temperature increased rapidly in combustion studio. This cycle can make fuel burn fully in the oven, and produce great heat value.

Solid coal can be gasified into inflammable gases through vapor media. This coal gas is then roughly de-dusted and conveyed through a conveying pipe to burn at a nozzle. The heat produced is used to heat the thermal furnace. With the gas as the burning material, the temperature is even on the furnace.

Our single stage coal gasifier is widely used as steel rolling furnace, annealing furnace, forging furnace, steel pipe furnace, glass furnace, aluminum furnace, melting furnace, cooper furnace, pottery furnace, etc.

Main Technical Parameters of the Coal Gas Generator

Main Technical Parameters of the Coal Gas Generator

|

Model |

QM0.8 |

QM1.0 |

QM1.2 |

QM1.5 |

QM1.6 |

QM1.8 |

QM2.0 |

QM2.4 |

QM2.6 |

QM3.0 |

QM3.2 |

|

Chamber diameter(mm) |

800 |

1000 |

1200 |

1500 |

1600 |

1800 |

2000 |

2400 |

2600 |

3000 |

3200 |

|

Hearth active surface(m2) |

0.5 |

0.785 |

1.13 |

1.77 |

2.01 |

2.54 |

3.14 |

4.52 |

5.31 |

7.07 |

8.00

|

|

Suirable fuel |

weak coherent gas carbon, anotherracite, burnt carbon |

|

Fuel granularity(mm) |

25-80 |

|

Fuel consumption quantity (kg/h) |

40-100 |

70-140 |

120-190 |

160-350 |

350-460 |

500-600 |

500-720 |

700-1040 |

850-1200 |

1700-2000 |

1800-2200 |

|

Gasifying agent |

Air, steam |

Gas yield

(Nm³ /h) |

140-350 |

245-490 |

420-670 |

560-1200 |

1200-1600 |

1500-2100 |

1750-2500 |

2500-3600 |

3000-4300 |

6000-7000 |

6500-7500 |

|

Gas calorific valu(Kj/Nm³ |

5020-5670 |

5020-6000 |

|

Water jacket heating area() |

4.02 |

5.02 |

6.78 |

10.37 |

11.06 |

12.44 |

17.58 |

21.87 |

23.69 |

30.16 |

31 |

|

Steam outputkg/h |

60 |

80 |

130 |

200 |

220 |

260 |

350 |

420 |

600 |

840 |

900 |

|

Gas outlet temperature |

(400-500)Plants related with the coal |

(400-500)Plants related with the coal |

|

Gas outlet pressure(Pa) |

1000 |

980-1470 |

1470-1960 |

1470-1960 |

|

Gas exportation diameter(mm) |

219 |

325 |

325 |

426 |

426 |

529 |

630 |

720 |

820 |

1020 |

1050 |

|

Air pressure(Pa) |

3000 |

4000 |

4000

|

|

Saturated air temperature |

50-60 |

50-65 |

|

Ashpan rotational speed(r/h) |

0.177-1.77 |

|

|

|

|

Equipment gross weight(t) |

3.5 |

4.5 |

5 |

7.5 |

10 |

20 |

23.4 |

29.8 |

32 |

37.6 |

38 |

|

Complete machine power(kw) |

6 |

6 |

6 |

7 |

8 |

10 |

14 |

20 |

20 |

27 |

27 |

|

Tuyere diameter(mm) |

108 |

108 |

140 |

165 |

219 |

325 |

325 |

426 |

426 |

426 |

426 |

| Prod Model: |

QM0.8, QM1.0,QM1.2,QM1.5,QM1.8,QM2.0,QM2.4,QM3.2 |

| Markets: |

South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Applicable Coal: |

Anthracite, Bitumite, Coke |

| Coal Size: |

25-80mm |

| Min Gas Yield Of One Set: |

140m3/H |

| Working Time: |

24h |

| Installation: |

Engineer Guide at Site |

| Shipping: |

Standard Container, Fr, in Bulk, etc. |

| Warranty: |

1 Year |

| Service: |

Whole Using Life |

I. About us:

Located in Zhengzhou, China, Henan Hongji Mine Machinery Co., Ltd. is a joint-stock enterprise, specializing in R&D, manufacture, and sales of large and medium-sized Mining Machinery (Crushing machinery, seperation/ore benefication machinery, screen and so on), NPK Fertilizer Equipment, and Building Material plants like Quick Lime Plant and Cement Plant. Our customers' satisfaction is our ultimate goal, and in order to achieve this, we strive to consistently provide high-quality products at the lowest prices.

II. Our products:

As the largest mine machinery manufacturing enterprise in Zhengzhou, we provide environment-friendly Mining machines, including flotation machines, classifying equipment, magnetic plants, ball mills, spiral classifiers, vibrating screens, crusher, sand making machines, and dryers, NPK Fertilizer Machines including Mixer, Rotary Dryer, Pelletizer, Coating Machine, Drum Screen, Bagging machineetc. These products have received ISO9001: 2000 certification and SGS certification, and are popular in Vietnam, Myanmar, Bengal, Laos, Philippines, Peru, Iran, India, etc.

We also provide preferential wearing parts when you purchase our products.

III. Applications:

Our products are widely used in the production operations of crushing plants, cement plants, lime plants, and concentrating mills. Their specific applications are as follows:

Ball mills grind many types of ore and other materials, and are widely used in mining, the chemical industry, etc.

Spiral classifiers are used in the distribution of ore, the grading of ore and fine silt in gravity mills, and for grading granularity of ore pulp in metal ore-dressing processes. They are also useful for de-sliming and dehydrating in the ore-washing process.

Vibrating screens can be used for grading materials in coal dressing, metallurgy, mining, power stations, construction and chemical industries, etc.

Rotary kilns are suitable for mechanical, physical, and chemical treatments of solid materials. They are applicable in the building industry, metallurgy industry, chemical industry, etc.

IV. Quality and Cost Control:

To ensure the quality of our products, we have formed cooperation with scientific research institutes in European countries, thus enabling us to introduce internationally advanced processing techniques and production lines to our operation. In addition, our incoming raw materials and our finished products are inspected 4 times before they are accepted or sold. We purchase our raw materials in large quantities, which help to reduce costs. We also save on labor costs by training our staff in-house. These steps and more enable us to provide crushing machines, mining machines, sand making machines, rolling mills, and cement equipment at a lower price than other manufacturers in this field.

V. Customer Services:

1. Pre-sale services:

We will happily assist you in getting the information you need to make a decision on which products best fit your needs. We want you to feel good about your purchase.

We can design and manufacture products as per your special requirements.

If required, we can train your technical personnel for you.

2. Services during the sale:

We strictly adhere to the principle of "the customer first". Your needs and concerns will be addressed to your complete satisfaction.

We can help clients to draft solutions to their specific situations.

3. After-sale services:

Our products are all guaranteed for a full year. During this period, if there is any quality problem, we repair it free of charge.

If needed, we can help you to install your equipment and train your operators on-site.

Inspection personnel will be sent to examine your equipment regularly.

If there is any problem, we will take measures to solve it immediately, on-site.

Technical exchanging is also provided for you.

For larger items, we can provide additional maintenance.